Product

.jpg)

.jpg)

The air quality in China presents a significant seasonal difference. When the southwest monsoon is blown in summer, the concentration of Fine Particle (PM2.5) in the atmosphere can reach good quality standards. When the northeast monsoon prevails in the early spring of winter, it becomes obviously worse. Haze phenomenon, both long-term and short-term exposure to this environment, will increase the risk of respiratory diseases and death. In order to solve this problem, it is impractical to seek changes in weather patterns. The focus is to reduce air pollution emissions. The major sources of air pollution emissions are: "fixed pollution sources" and "mobile pollution sources." Fixed sources of pollution refer to sources of pollution that cannot be repositioned, such as thermal power plants, waste incinerators, chemical industry processes, diesel engines, and other factories that use fuel heating. The sources of mobile pollution are like the emission pollution that can be moved by steam locomotives, diesel vehicles, public transportation, ships and aircraft.

.jpg)

Fixed sources & mobile sources (Source: National Institutes of Health)

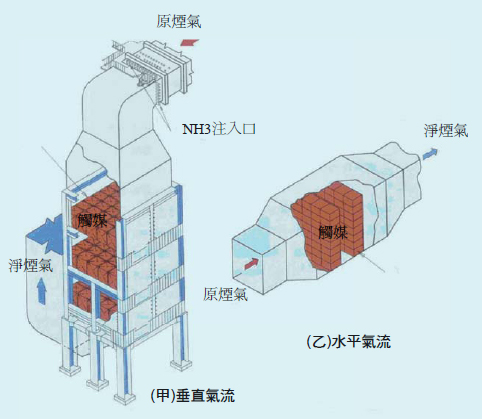

At present, there are three possible control options for fixed pollution sources, namely: Selective Denitrification Catalyst Reactor (SCR/SNCR), Electrostatic Precipitator (EP), and Flue Gas Desulfurization System (FGD). Among them, the selective denitrification catalyst reduction reactor (also called flue gas denitrification technology) is one of the best feasible technologies adopted for global air pollution control, and it is recognized that it can efficiently handle "nitrogen oxides" ( The most effective method of NOx). The SCR / SNCR system is highly stable and technically sophisticated, with hundreds of SCR / SNCR plants in operation worldwide. There are also more than 50 plants with SCR / SNCR equipment in operation or construction in Taiwan. The EPA has continued to implement pollution source control and implemented measures to reduce and remove air pollution prevention fees, making the installation of SCR / SNCR plants even more valuable. (For a mobile pollution source solution, see the Novax website at www.novax-material.com.tw)

SCR / SNCR selective denitrification catalyst reduction reaction equipment (also known as: flue gas denitrification technology)

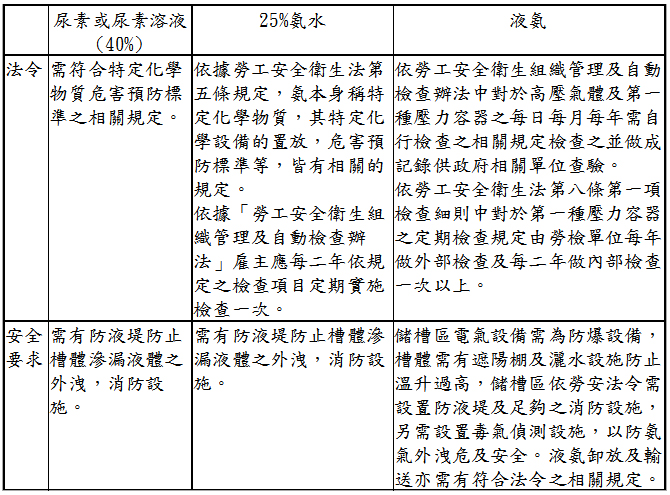

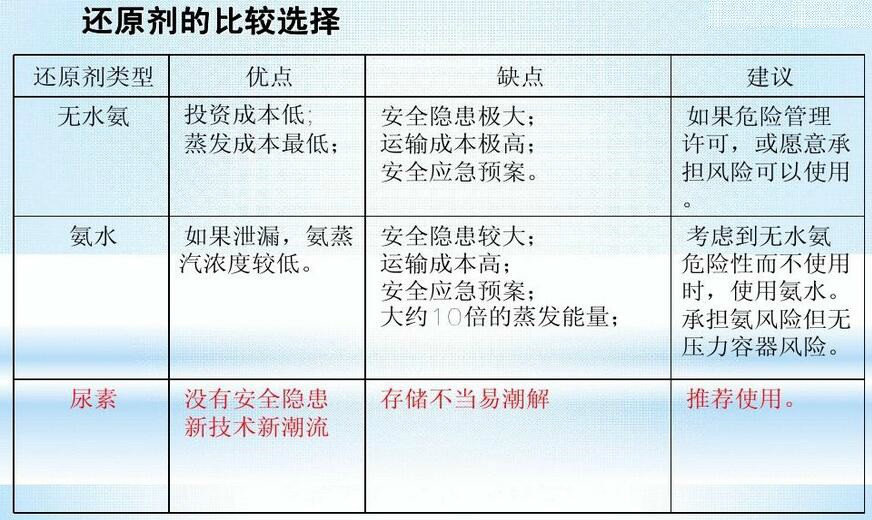

SCR / SNCR generally uses ammonia (NH3) as a reducing agent to react with the nitrogen oxides in the exhaust gas to produce harmless nitrogen (N2) and water (H2O). At present, there are three kinds of reducing agents used in SCR / SNCR: Anhydrous Ammonia, Ammonia Water and Urea. As liquid ammonia and ammonia are toxic chemical substances in the safety regulations, they have the hazards of burning, explosion and corrosion, which pose a high risk to the operators and the surrounding environment. Urea, on the other hand, is a non-toxic, harmless chemical that is non-explosive and completely non-hazardous. Therefore, several advanced countries in the world have gradually replaced urea with liquid ammonia and ammonia as reducing agents for SCR / SNCR.

Comparison of the safety of liquid ammonia, ammonia, and urea

Urea is the largest consumable in SCR / SNCR equipment, and its cost of consumption directly affects the overall benefit assessment of denitrification system (De-NOx). The highly reactive urea solution is injected into the denitrification reaction zone through the ammonia injection nozzle line, so that it is fully mixed with the flue gas and reacts with NOx in the flue gas at 350-800° C. to achieve NOx removal. The purpose is to reduce the impact on air quality.

Novax supplies different grades of urea products

Nova is one of the world's leading suppliers of AdBlue®, and also supplies urea and urea solutions for SCR / SNCR equipment such as thermal power generation, waste incinerators, chemical industry processes, and diesel engines. From the agricultural level, automotive level to industrial level, various grades of urea products are readily available. In addition to having enough production capacity to serve customers around the world, Nova meets the market demands for "fixed sources of pollution" and "mobile sources of pollution", and is constantly striving to improve the quality of the environment, hoping to set a new model for Taiwan's green enterprises.

Urea related products sales and consulting services, welcome to inquire: +886-3-3583289

E-Mail: yang@novax-material.com